- Jan 16, 2026

Axial Pile Analysis: Episode 2 - Understanding Resistance Stages in Driven Pile Design

- The Geotechnicals

- Notes on Axial Pile Analysis

- 0 comments

Unlike bored piles, driven piles experience a range of resistance stages — each with a different purpose and behavior. As engineers, recognizing these distinctions is key to accurate capacity assessment and proper design documentation.

Here are the three primary resistance states to be aware of:

🔹 Ultimate Axial Resistance

This is the long-term capacity of the pile — including shaft resistance and toe resistance — with adjustments for downdrag (negative skin friction) and scour (loss of soil support) if present.

This is the value we rely on for design under service and ultimate loads.

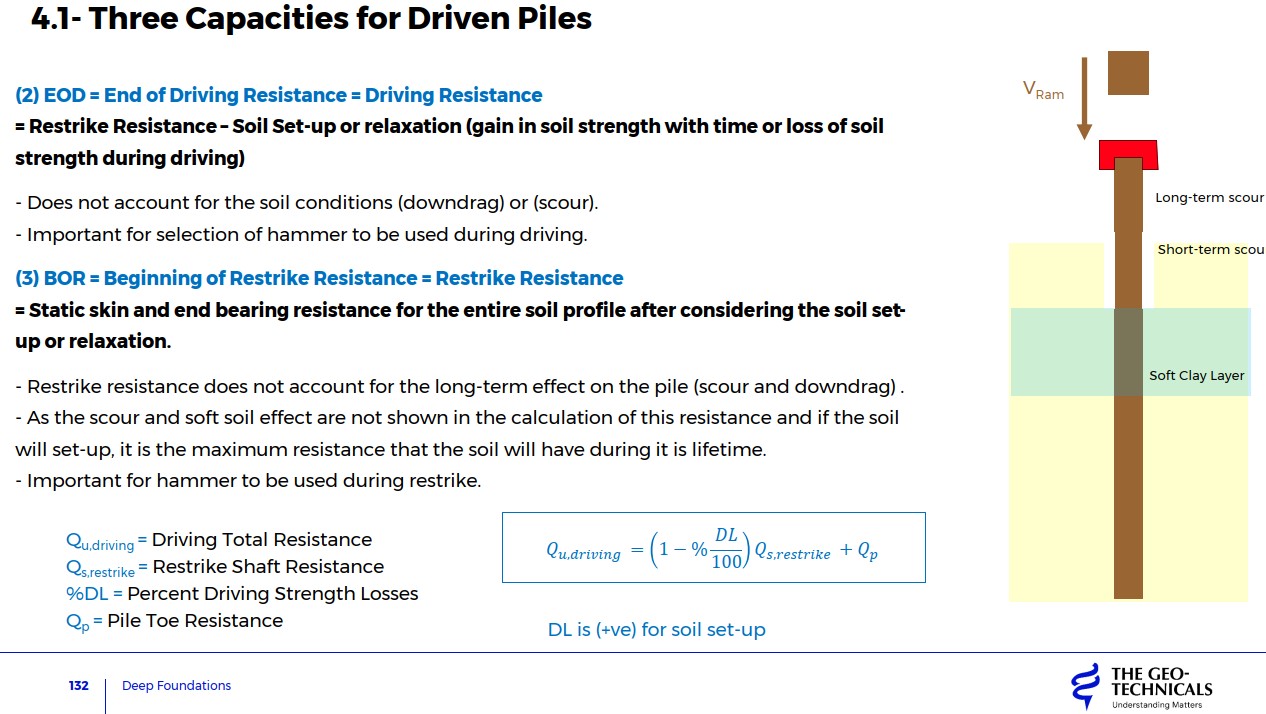

🔹 End of Driving (EOD) Resistance

This is the capacity immediately after pile installation, when the surrounding soil is still disturbed. It reflects the minimum expected resistance and is often used for drivability analysis or to verify hammer performance.

Important: EOD does not represent long-term capacity.

🔹 Beginning of Restrike (BOR) Resistance

Measured hours or days after driving (typically with dynamic testing), this value reflects the effect of setup (strength gain) or relaxation (strength loss) depending on soil type.

Setup is common in clays due to pore pressure dissipation.

Relaxation may occur in dense sands or sensitive silts.

Understanding the time-dependent nature of these changes — and their impact on capacity — is critical for reliable pile acceptance and long-term performance.

I cover this topic in depth in my new Module,

“Module (3a) Deep Foundations – Axial Pile Analysis with RS Pile”